Showroom

Powder Coating Machine works by applying dry colour powder to a metal surface, before baking the colour onto the surface using heat to form a hard finish. This machine gives the powder a positive charge, which is attracted to the ground metal surface.

Powder Coating Gun uses a high-voltage generator to disassociate air and produce a stream of negative or positive ions, which in turn imparts a like charge to the powder cloud. This gun is usually used to create a hard finish that is tougher than conventional paint.

Powder Booth designs consist of batch, cartridge batch collector-style, pass through, and lab powder booths. This booth enables businesses to produce more high-quality powder coating finishes. This booth provides a bright, efficient environment for powder application. This booth engineered for excellent performance and efficiency.

Powder Oven provides uniform air distribution along the entire length of the work chamber resulting in quality cured finishes and optimum cure cycles. This oven is designed to prevent powder blow-off which reduces rework, saving you time and money. This oven typically requires significantly decreased curing times to the drying periods of liquid paints.

Powder Coating System is usually a system where the parts are prepared, coated and cured in batches of multiple parts, with operators handling up to dozens or hundreds of parts at a time. This system is usually hung on metal rolling racks, which move with the parts throughout the coating process.

Powder Coating Accessories are in popularity because they are easier, more economical and more efficient than traditional automotive painting. These accessories help to reduce time, expense and hassle while producing an amazing finish. These accessories are very cost effective and easy to install.

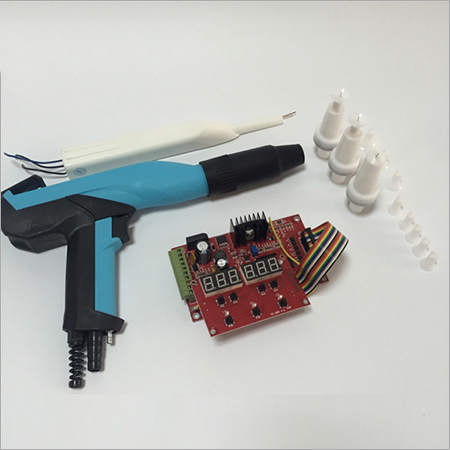

Parts of Control Unit are widely used in powder coating machines and also helps in generating an electric field with the opposite pole. These parts combine to provide the powder coating which is further used for coating of metals, such as household appliances, aluminium extrusions, drum hardware, automobile, motorcycle, and bicycle parts.

Parts of Spray Gun are widely used for constructing the spray gun for further use. The gun developed originally from the airbrush, is used for less delicate work, such as applying lacquers, paints, varnishes, shellac, and other finishes to manufactured articles.

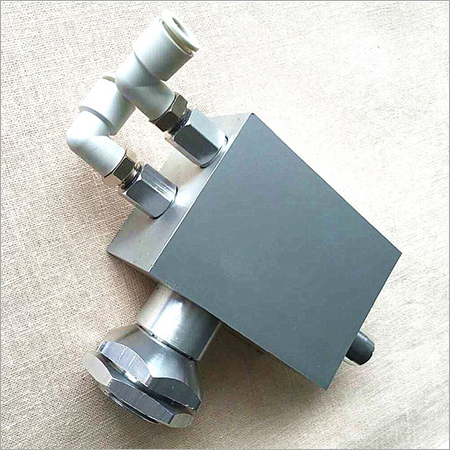

Powder Coating Pump Injector is mainly used to convey normal organic powders between the powder hopper and the powder gun. This injector is a plug-in type and permits easy handling and quick cleaning. All connections are plug-in types. The injector can be disassembled without special tools.

Nordson Powder Coating Parts are used for the production of powder coating which can be further used for different purposes. Our company provides a complete line of accessories and auxiliary equipment for powder coating. These parts are easy to use and highly durable in nature too.

The Wagner Powder Coating Parts are designed for easy dispersal and function. These parts are provided with advanced accuracy in functions and good functionality. Their performance allow for good surface finishing.

Powder Coating Nozzles can be used with an extension on your powder coating gun, helping you get into hard-to-reach places like inside pipes and tubes. These nozzles also enhance your powder coating abilities. These nozzles are easy to install and safe to use.

Get in touch with us